¥ 价格面议

¥ 价格面议

¥ 价格面议

¥ 价格面议

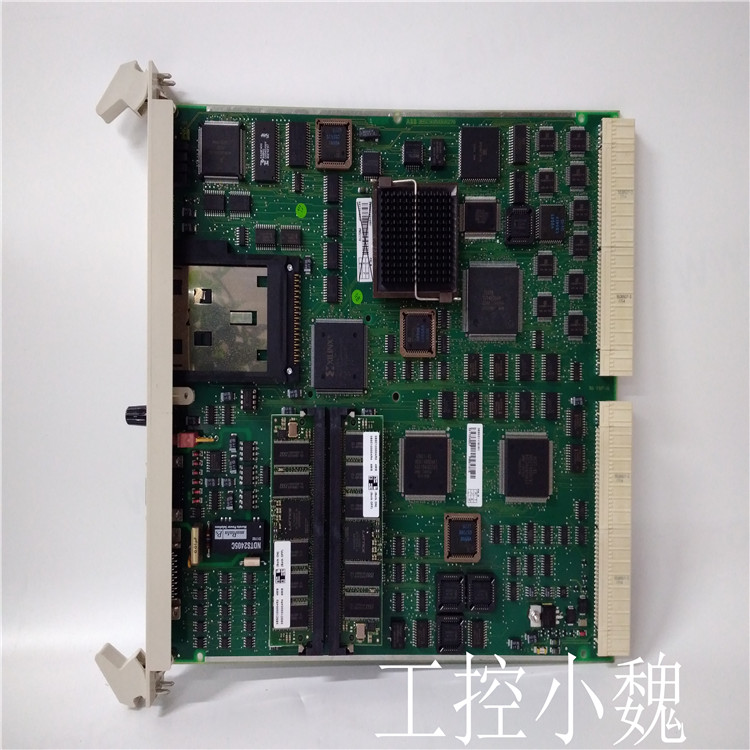

易卖工控网(www.ymgk.com)提供”PM511V16 3BSE011181R1备件ABB”,产品详情:品牌/厂家:ABB、型号:PM511V16 3BSE011181R1、成色:全新、货期:现货 1天内发货、保修:180天,更多产品详情就上易卖工控网。

PM511V16 3BSE011181R1

PM511V16 3BSE011181R1ABB机器人挑战建筑结构场外预制ABB机器人协助美国建筑公司Autovol完成更精准的场外预先建造,为该公司带来更低的建筑成本、更少的建筑时间以及更高的精准率。Autovol作为一家将部分建筑提前建造后运输到施工现场的预先建筑公司,利用ABB机器人来完成房屋的墙体、地面和屋顶的自动组装工程,机器人自动化为整个建筑流程节省了高达40%的时间。ABB IRB 2600墙体自主钻孔应用迅达作为电梯和自动扶梯供应商,与ABB机器人合作启动了“机器人电梯安装系统”试点项目

并选择ABB IRB 2600工业机器人来进行试验。该款机器人的臂展达1.65米,有效载荷为29公斤,主要任务是在电梯井中钻孔并安装锚栓。该项目包括一个自主安装系统,IRB 2600被安装在一个可在电梯井中上下移动的临时升降机上,通过编程使其以毫米级精度在相同的坐标上钻孔。ABB离线编程仿真软件RobotStudio

ABB机器人和ABB离线编程仿真软件RobotStudio通过瑞典斯堪卡建筑集团的试验,结果达到了提高钢筋结构制造速度和效率的目标。近年来,斯堪卡一直致力研究使用机器人来生产辅助固定混凝土结构的钢筋笼。ABB机器人在钢筋的自动化捆扎生产应用,将钢筋结构的生产时间从每吨16小时缩短至仅1小时,大幅加快项目时间进度。此外,在瑞典境内用机器人现场制造钢筋结构,可减少运输和相关污染。

ABB机器人定制化生产减少能耗

木材的延展性和可加工性使其非常适合于机器人自动化,不会造成太多损耗。加拿大智慧城市公司携手ABB机器人在预制生产线上加工、搬运和组装大块木材。机器人在工位中作业,按照Intelligent City公司的平台(P4L)设计软件中所构建的设计来生产木材组件,从而能够根据客户的特定要求来建造定制结构。ABB的离线编程软件RobotStudio也可以与P4L平台搭配使用,从而为ABB机器人规划任务和动作。

Foxbore (福克斯波罗) : I/A Series 系统,FBM 全系列(现场输入/输出模块)

顺序控制、梯形逻辑控制、事故追忆处理、数模转换、输入/输出信号处理、数据通信及处理等。

Vestinghouse (西屋) : 1C31 系列DCS系统、CPU、OVATI0N 系统、WDPF系统、WEStation系统备件。

Triconex (英维思) :冗余容错控制系统、基于三重模件冗余(TMR) 结构的0现代化的容错控制器。

维修ABB触摸屏常见故障现象:

⊙ 开机主机指示灯正常,但是显示器显示无信号输入(黑屏);

⊙ 按下开关键,主机无任何反应(指示灯不亮,听不到主机启动的声音);

⊙ 电脑反复重启,伴随死机、花屏;

⊙ 屏破损、碎裂;

⊙ 显示屏有亮,摸出无反应;

⊙ 开机后不能进入windows画面或停在画面不动;

⊙ 无法安装操作系统;

⊙ windows系统经常出现非法操作或出现各种出错英文字母或代码;

⊙ 电脑运行速度明显比以前慢,甚至有时会死机;

⊙ 开机BIOS检测不到硬盘;

⊙ 系统启动很慢,文件能看到但是打不开;

⊙ 硬盘不能分区格式化;

⊙ 显示器出现偏色、缺色以及花屏;

⊙ 显示器只看到一条横的亮线或纵向的两线,无图像;

⊙ 打开显示器电源按钮后,显示器没有任何反应;

⊙ 打开显示器故障指示灯闪烁,屏幕无图像;

⊙ 显示器内部有“吱吱”的响声,屏幕图像时大时小或黑屏;

⊙ 显示屏图像严重变形,用功能键调整无任何变化;

⊙ 显示器屏幕很暗,几乎看不到图像,用功能键调整无任何变化;

PLC及其体系结构:

随着自动化水平的提高,dcs控制系统(集散控制系统)逐渐代替了常规仪表,其优越性已被广大操作人员所接受。但发生故障时,会造成装置停车甚至事故,各种故障如何及早发现及恰当处理就显得非常重要。

1、查看监控画面的数据

出现以下情况时,说明控制系统发生问题,应立即通知微机维修人员维修,同时操作工到现场进行处理。

(1)经常变化的数据长时间不变,且几个数据或所有数据都不变。

(2)控制分组画面中,手动自动无法切换,或手动输入数据后,一经确认,又恢复为原来的数据,修改不过来。

(3)趋势图画面中,几条趋势都为直线不变。

(4)监控画面中,多个数据同时波动较大。

判断波动数据是否为工艺上相关参数,若是相关参数则通知仪表及微机人员检查,看是否某调节系统波动引起相关参数变化,同时将相关调节系统打到手动状态,必要时到现场进行调节。如水溶液全循环装置中,尿素合成塔压力正常时为l9.67MPa,如果突然大范围波动,此时势必引起下游的中压系统、低压系统压力波动,这种情况是由于几个相关参数中某一参数波动引起其他参数变化,并不是控制系统本身故障。

若波动数据工艺上彼此并无直接影响,则可能为微机某卡件发生故障,立即将相关自调系统打到手动调节,必要时到现场进行调节,同时,通知微机及仪表人员检查。

2、查看操作站工作情况

当发现某个操作站死机,监控画面数据不刷新,调节画面不起作用,查看右上方系统报警指示灯是否正常,并检查其他操作站是否工作正常,若正常,则仅该操作站有问题,通知微机维修人员修理。若其他操作站数据也不变,则为系统通讯网络出现故障,立即通知维修人员检查网络设备的运行情况,进行修复。

3、观察操作站的断电情况Point estimation

When estimating I / O points, appropriate margin shall be considered. Generally, 10% ~ 20% expandable margin shall be added according to the statistical input / output points, which shall be used as input / output point estimation data. During the actual ordering, the input and output points shall be rounded according to the product characteristics of the manufacturer's programmable logic controller. [5]

Memory capacity

The memory capacity is the size of the hardware storage unit provided by the programmable controller itself. The program capacity is the size of the storage unit used by the user application items in the memory, so the program capacity is smaller than the memory capacity. In the design stage, since the user application program has not been prepared, the program capacity is unknown in the design stage and needs to be known after the program debugging. In order to estimate the program capacity in the design and selection, the memory capacity estimation is usually used instead. [5]

There is no fixed formula for estimating the memory capacity of the memory. Many literatures have given different formulas, which are generally 10-15 times the number of digital I / O points, plus 100 times the number of analog I / O points. This number is the total number of words of the memory (16 bits are one word). In addition, the margin is considered as 25% of this number. [5]

Control function selection

The selection includes selection of characteristics such as operation function, control function, communication function, programming function, diagnosis function and processing speed. [5]

1. Arithmetic function

The operation functions of the simple programmable logic controller include logic operation, timing and counting functions; The operation function of the general programmable logic controller also includes the operation functions such as data shift and comparison; The more complex operation functions include algebraic operation and data transmission; The large-scale programmable logic controller also has analog PID operation and other advanced operation functions. With the emergence of open systems, all programmable logic controllers have the communication function. Some products have the communication with the lower computer, some products have the communication with the same computer or the upper computer, and some products also have the function of data communication with the factory or enterprise network. The design and selection shall be based on the requirements of practical application, and the required calculation functions shall be reasonably selected. In most applications, only logic operation and timing and counting functions are required. In some applications, data transmission and comparison are required. When it is used for analog quantity detection and control, algebraic operation, numerical conversion and PID operation are used. Decoding and encoding are required to display data. [5]

2. Control function

The control functions include PID control operation, feedforward compensation control operation, ratio control operation, etc., which shall be determined according to the control requirements. Programmable logic controller is mainly used for sequential logic control. Therefore, single loop or multi loop controller is often used to solve the control of analog quantity in most occasions. Sometimes, intelligent input / output unit is also used to complete the required control function, so as to improve the processing speed of programmable logic controller and save memory capacity. For example, a PID control unit, a high-speed counter, an analog unit with speed compensation, and an ASC code conversion unit are used. [5] Automation technology is widely used in industry, agriculture, scientific research, transportation, commerce, medical treatment, service and family. The adoption of automation technology can not only liberate people from heavy physical labor, part of mental labor and harsh and dangerous working environment, but also expand the functions of human organs, improve labor productivity and enhance the ability of human beings to understand and transform the world.

Automation is a high-tech company specializing in the R & D, production and sales of intelligent automatic control, digital and networked controllers and sensors. Its numerous functional modules and perfect embedded solutions can meet the personalized needs of many users. The company has a variety of products to meet the needs of customers. The automation equipment is composed of vibrating plates.

significance

Large complete sets of equipment in the automation system, also known as automation devices. It refers to the process of automatic operation or control of a machine or device according to specified procedures or instructions without human intervention. Therefore, automation is an important condition and significant symbol for the modernization of industry, agriculture, national defense and science and technology.

Check all power, air and hydraulic sources

Power supply, including the power supply of each equipment and the power supply of the workshop, i.e. all the power supplies involved in the equipment.

Air source, including the air pressure source required by the pneumatic device.

The hydraulic source includes the working conditions of the hydraulic pump required by the hydraulic device.

In 50% of the fault diagnosis problems, basically the errors are caused by the power supply, air source and hydraulic source. Such as power supply problems, including power supply faults of the whole workshop, such as low power supply, burnt fuse, poor contact of power plug, etc; The air pump or hydraulic pump is not opened, the pneumatic three-way or two-way parts are not opened, and the relief valve or some pressure valves in the hydraulic system are not opened. These basic problems are usually common problems.

Check whether the sensor position is offset

Due to the negligence of the equipment maintenance personnel, the position of some sensors may be wrong, such as not in place, sensor failure, sensitivity failure, etc. The sensing position and sensitivity of the sensor shall be checked frequently, and the deviation shall be adjusted in time. If the sensor is damaged, it shall be replaced immediately. In many cases, if the power supply, air source and hydraulic source are guaranteed to be correct, more problems are sensor failures. In particular, due to the use of magnetic induction sensors, it is likely that the internal grounding wires are stuck to each other and cannot be separated, resulting in a normally closed signal. This is also a common fault of this type of sensor and can only be replaced. In addition, due to the vibration of the equipment, most of the sensors will be loose after use. Therefore, during daily maintenance, it is necessary to frequently check whether the position of the sensor is correct and whether it is fixed firmly.

Check relay, flow control valve and pressure control valve

The relay, like the magnetic induction sensor, will also have grounding adhesion when used, which cannot guarantee the normal operation of the electrical circuit and needs to be replaced. In pneumatic or hydraulic systems, the opening degree of throttle valve and the pressure regulating spring of pressure valve will also loosen or slide with the vibration of equipment. Like sensors, these devices are components requiring routine maintenance in the equipment. Therefore, in daily work

Speaking of AI, many people can trace back to the imagination of science fiction writers nearly 100 years ago or the hypothesis put forward by Turing 64 years ago. But in my opinion, the whole history of human civilization has been permeated with the pursuit of machine intelligence. For example, the abacus, which Mr. Yang Zhenning called "the earliest computer in the world", was a mainstream computing tool until the popularity of PC. in the 1970s and 1980s, many Chinese parents sent their children to learn mental arithmetic and abacus - the abacus itself is a tool that is endowed with rules and reflects human wisdom. In essence, it can be said to be in the same strain as today's PCs, smartphones and tablet devices.

若部分操作站突然无显示,则说明UPS或市电断电,立即通知微机维修工进行维修。若有电的操作站可正常监控,此时不会影响控制系统的正常调节。