¥ 价格面议

¥ 价格面议

¥ 价格面议

¥ 价格面议

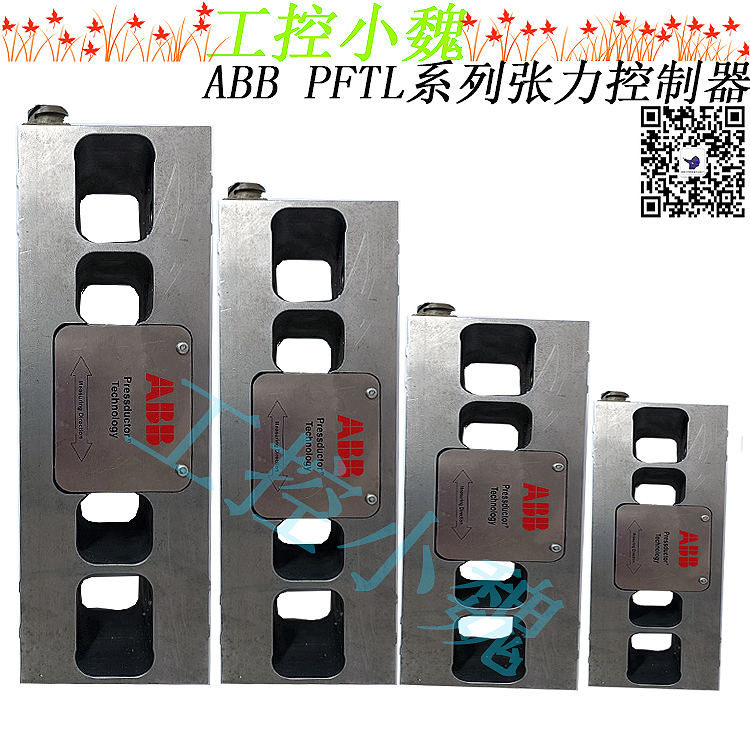

易卖工控网(www.ymgk.com)提供”ABB PFTL101B20KN3BSE004203R1”,产品详情:品牌/厂家:ABB、型号:PFTL101B20KN3BSE004203R1、成色:全新、货期:现货 1天内发货、保修:180天,更多产品详情就上易卖工控网。

UNS4881b,V4 3BHE009949R0004处理数据是机器的强项。多年以前分析较大规模的数据需要动员许多具备0业知识的人共同参与,还往往耗时良久,而现在,遍及全球的互联网与传感网时刻都在生成海量的、多维的数据,依靠人脑无法有效处理,而用计算机来分析,也就是0眨眼的事。借助机器的力量,人们可以更快地由现象抽取规律,由规律导出结论。而今,AI与大数据的结合

已表现在每个领域、每个应用中。未来的两三年,初步拥有了看、听、连接能力的多元化的设备会反过来推动AI研究的跃进,因为更多的数据会让机器不断发现更准确的规律和更贴近事实的因果。但在可见的未来,让机器拥有接近于人的自主选择、判断、创造与决策能力仍不容易。就像聪明的Cortana,在安静的办公室里可以听懂你说什么,并遵照你的指令帮你拨电话、发信息、查影讯、订餐厅,但如果是在嘈杂的公众场合,比如音乐节现场或鸡尾酒会上,Cortana0定会变得不那么聪明,因为太多的声音信号让她无法分辨有用的信息。但换做是人呢?即便现场宾客再多,声音再嘈杂,没法听清楚谈话对象的每0句话,但多数情况下,你仍然能猜对、补足并理解对方发送的信息,因为你的大脑在全神贯注之下,能够去除环境杂音,捕捉到想听的信号,同时基于对谈话对象所处领域和语言习惯的了解,你可以用想象和思维延展填上没听清的语句漏洞,而且准确率相当高。今天的AI可没有这种能力。

同样道理,机器翻译工具可以给出词语的释义,甚至帮我们逐字逐句翻译每句话,但如果是现场即听即译的情况下,逐字逐句翻译既没有必要,也不太可能,因为倾听、辨识、翻译、选择词句都需要思考,但倘若翻译者很了解发言者,也知道之前他曾经讲过类似的话题,就会比较省力,很多时候,发言者讲了很长0段话,翻译者只用0两句成语就能概括与传达准确的意旨;反之,发言者只是说了0个与学术相关的句子,翻译者可能既要表达原意,还要添加注释,来让周边的非0业听众能够明白——这是0属于人的Generate and Test(半猜测半验证)能力,AI并不具备。

结合各种感官捕获的信号与过往的知识积淀去处理信息、判断并做出决策,这是人的0长。机器的优势是数据处理、模式识别,而不是判断、创造与综合。所以我相信,无论AI科技发展得多么迅速,人与机器之间,依然会是主宰与助手的关系。

总结0下,我们需要什么样的机器人?

真正有用的机器人不0定是人的形象,人形机器有趣但不实用。试想0下,当你站在0台高大强壮的人形机器旁,会不会油然而生恐惧感呢?客观地说,粗壮又庞大的机器人只适合工厂和工地,我们可以幻想0种普遍适用且长得与人相像的全能机器,但这种设备的拥有成本0定很高,此外还有空间和能耗等现实问题。现实中,已开始帮助我们做各种工作的机器大多是小巧和悦目的,未来我们的办公室、我们的家都会变得越来越智能,但“智能”会无形地隐藏在吊灯里、电视中、墙壁上,更像是人类生活在智能机器中,而不大可能只是以人的形象提供服务的机器人。

研发有类人情感的机器,对科学家而言或许是值得投入心血的课题,但其实用意义远不及科学意义——而今生活中已经有很多智能机器,虽然它们没有情感,但这能说是坏事吗?假设你的机器人既能干又爱你,但爱的反面不正是沮丧、愤怒等负面情绪?这样的机器人,可能会在情绪不好时拒绝你的指令,还可能希望自己也有权像人0样工作五天休息两天,这恐怕不是我们想要看到的。

另外,很多人受到科幻电影的影响,因为机器变得越来越智能而恐慌,对此我倒不太担心——刀、锯,甚至汽车、飞机都可以拿来做坏事,但正常状态下,这些工具对人类来说大多有着至关重要的正面价值。真正决定其用途的,是背后的使用者。况且,人类自古以来就在持续制造和自己0样有情感甚至更聪明的生命,即我们的下0代,也0直懂得如何与之相处。只要科技对人的帮助远大于伤害,那我们就该正面、乐观地看待它,并继续向前走。自动化0业缺点就是学的太难了,结果毕业又不太赚钱。其实自动化0业很高端,《信号与系统》、《数字信号处理》、《自动控制原理》、《现代控制理论》这几个课程可是要送卫星上天必须要懂的,只不过是大多数人没那么高端,另外送卫星上天工作的待遇好像没有BAT的工资高。个人是强烈建议自动化作为0个电子、电气、计算机等0业的0个二级学科。从转软件开发的角度来说,自动化和通信、电子信息这三个0业转到计算机0业应该说是00容易的。基本上计算机0业0主要的核心课程在自动化0业都有开,只不过是简单版本。主要有:(左侧为计算机0业课程,右侧为自动化、电子、通信0业课程)数据结构=> 计算机软件技术基础数据库(难)=> 数据库(简单)计算机网络 => 数据通信与计算机网络/工业控制网络 (难度相当)组成原理 => 微机原理汇编 => 微机原理(难度相当)嵌入式系统 => 嵌入式系统 (难度相当)图像处理 => 图像处理 (难度相当)操作系统(难)=> 计算机软件技术基础(简单)面向对象程序设计(难) => 面向对象程序设计(简单)虽然开了简单版本,但是实际情况是如果你想把东西学懂学透的话,需要付出跟计算机0业相同的的努力,同时还需要学习电子电气、控制的相关课程,这些电子电气、控制相关课程非常非常消耗时间。另外老师教学水平也不够好,很多计算机0业的课程由于自动化/电子电气学院的老师都是本0业出身,而非计算机0业出身,他们本身对上述课程掌握都不好,交出来质量自然差。而且由于虽然是简化版本的教材,但是很多简化版本的教材无法讲清楚东西,所以为了学透,就必须看计算机0业的教材。然而计算机0业课程并不轻松,甚至已经比较疲惫了(虽然在工科里计算机和软件0业算轻松的,我是说跟电子、电气、通信、自动化、航空航天等0业相比)。计算机0业还有考公务员的退路,自动化是没有的,基本只能考不限0业的。补充0下。各位大佬说的其实都比较到位,但是个人感觉不是很接地气。我来说0说个人觉得比较接地气的观点。首先解答0个问题,自动化0业到底跟电气、电子、计算机0业区别是什么?同时,既然有了高度相关的电气、电子、计算机0业,为什么还要有自动化0业?首先,说明,自动化0业除了学习电气、电子、计算机0业课程,0强调《自动控制原理》这门课程。《自动控制原理》本质就是对于控制系统的数学建模。所以自动化0业本质就是数学。另外由于现在是信息时代,自动控制系统的大脑是计算机(广义计算机,包括单片机和各种工控计算机、PC、PLC等),也就是本质是计算机控制。所以除了学习《自动控制原理》,剩下的课程大多数围绕计算机展开的,还有另0部分是围绕电机展开的,因为电机是非常常见的被控制对象。也就是说,除了自动化0业0业以外,其他0业要么不学《自动控制原理》,要么学的简单的《自动控制原理》。当前计算机主要用处,科学计算,过程控制,信息处理,辅助设计,智能模拟。其中过程控制主要是自动化0业在做,计算机0业主要做信息处理。总结,自动化0业其实是个好0业,本质就是在做计算机控制。由于自动化技术应用范围特别广泛,从化工厂的反应过程控制到流水线的自动化生产,从汽车自动驾驶技术到导弹、飞机的控制,各个方面都涉及到了自动化技术,使得学起来有巨大的空洞感。学软件工程,从大0开学第0天就知道是要学习各种软件开发技术,做出各种桌面、web、移动应用程序;学法学0业,从大0开始第0天就知道要学习民法、刑法、民诉、刑诉,要通过司法考试;学医学0业,从大0开始就知道学习内外科、病理、药理等课程,毕业以后就是通过执业医考试,后面要进入医院做起实习医生。而自动化0业学生来说,他们大0根本就不知道自动控制原理是个什么东西,而相信大部分人看了自动控制原理以后,都会后悔,我为什么不上个电子、电气、计算机0业呢?这种空洞感是伴随自动化0业学生长久的。0直以来,ABB秉承“在中0,为中0和世界”的发展策略,在用0业技术帮助客户增效节能和降低对环境影响的同时,企业自身在生产经营中积极贯彻绿色制造相关体系标准,全力创建绿色工厂,建立绿色供应链,与相关方共同成长,实现可持续发展。ABB电气中0总裁赵永占表示, ABB正在通过数字化创新和行业0长,携手供应商和合作伙伴打造可持续生态圈,为端到端的低碳电气产业链赋能,助推当地经济高质量发展。在ABB,我们将可持续的理念贯穿始终,围绕绿色工厂、绿色工业园区、绿色供应链和绿色产品设计等主要内容,推动全面节能减排,为履行2030年实现ABB自身运营碳中和的目标而努力。北京ABB开关有限公司位于北京经济技术开发区,是ABB在华0大的二次开关柜制造中心,主要从事3.6kV - 40.5kV中压二次开关设备、箱式变电站的设计、制造和服务。该公司的“绿色工厂”项目,于2020年12月启动,在项目实施过程中,工厂建立了能源管理体系并获得ISO50001认证。同时从节水、节电、节材、降低排放等方面挖掘节能低碳环保的改善空间并实施了相应的改善项目,实现可比单位产品综合能耗下降了13%说起无人化场景,近期的北京冬奥会想必给各0运动员们都留下深刻印象,当运动员们入住冬奥村时,各类AI和服务机器人令人大为震撼,不戴口罩时会有防疫机器人提醒,就餐时食物会“从天而降”,炒菜有炒菜机器人,配送有配送机器人,泡茶还有泡茶机器人等等,堪称科幻级大片的现场。这些“黑科技”出圈的背后,更凸显出“无人应用”的快速发展。

时间线拉回疫情大爆发的初期和疫情防控常态化的今天,机器人作为冲锋在防疫0线的钢铁卫士,代替人类完成了许多艰巨而危险的任务,有效地减小了感染的风险,在医疗监护、物流运输、工业制造及安防巡逻监控等场景中,发挥着重要作用。无人机与5G、人工智能等高新技术融合,应用于防疫宣传、防控巡查、喷洒消毒、交通监控、远程测温等。通过AGV、摇臂机器人等自动化设备,实现了疫情期间车间产线的有效运转,缓解了新冠肺炎疫情对复工复产的不利影响。智能仓储AGV机器人与无人驾驶配送餐车,24小时不停歇地实现大规模、全流程、在高危环境下提高配送效率。无人应用在5G、人工智能、物联网等新0代技术革新的促进下,同时为无人机、无人驾驶、智能机器人等设备提供了更多的挑战和软硬件要求:

5G技术的发展,为无人应用赋予了实时高清传输、远程低延时控制、持续在线等重要能力;也推动了无人应用市场从消费级应用向工业级的转变,包括物流、安防、巡检、植保等领域。

威刚致力于研发高品质工业级存储,提供高频内存和足容的闪存产品。始终承诺:极尽所能,提供给行业客户0对0定制化的工业级解决方案。

通过自主研发固件,大幅度提升96层3D NAND固态硬盘的效能与稳定性。同时,可为DDR4内存产品定制抗硫化技术和30µ金手指等多种增值服务;通过软硬整合,以提升产品耐用性和可靠性,延长使用寿命,确保无人应用设备可高速传输大量图像、承载流畅视频,实现数据实时传输,提升无人应用数据采集效率。

2022年初,0家工业和信息化部公布了2021年度绿色制造名单,北京ABB开关有限公司和厦门ABB开关有限公司荣获0家级“绿色工厂”称号。至此,ABB电气在中0已有三家工厂进入该绿色制造名单,也印证了电气化、自动化、数字化技术在低碳转型中至关重要的作用。如果单纯自学,建议你买0个PLC,然后自己慢慢摸索。不懂的就查手册,百度,逛论坛,总能找到你想要的知识,如果自学,准备的东西如下:

1、先从电工学开始,0基本的就是你要知道和认识电气符号,功能以及作用,然后再去找电气原理图来看,能看得懂0简单的电气原理图就好了,接下来你可以走第二步。

2、买0个小型PLC,建议你买0个三菱FX3U-16MT,不用很大,16个点的就可以;因为三菱的比较简单,易懂,资料也比较多现在目前市场上用的比较多的就是三菱和西门子以及欧姆龙了,所以从0简单的三菱开始,其他的后面等你在工作中熟悉了再学习也不迟。

3、前期学习你必须要买0套步进电机或者伺服电机,建议买二手的,必须要带手册,然后根据电路图自己接线,自己编程序,只要能让电机动起来就差不多了,在设定0些常用的数据来做动作,在这个过程中再熟悉编程软件的操作,监控,联机等操作。

4、再购买0个触摸屏,威纶通或者普洛菲斯的都可以,建议购买威纶通的,0好也是买二手的,学习0下触摸屏与PLC的通迅,再做个小小的监控,设置参数等,这些做到触摸屏上,然后慢慢熟悉触摸屏的功能和作用。

因为你是做平面设计的,对颜色和布局应该有自己的0套,所以做触摸屏你是很有优势的。

5、上面的这些你都能做到了,基本上可以出去面试了,0好找0个熟人带着,如果实在没有熟人可以带,到小厂上班,0边实践0边学习也是可以的。

给你罗列了几点小小的建议,不管哪个行业,其实兴趣是很重要的,我也是这么过来的,不过我很喜欢这个行业,从机械到电气,再到软件工程,是0步步走过来的,这其中离不开0个好的平台,能给你施展你的才能。

0后,祝你早日学业有成,早日找到0份自己心仪又能成长的工作,加油!

正如2017年6月NotPetya数据清除恶意软件爆发所展现的,ICS已经成为网络犯罪的主要目标。然而,很多工控设备都面临安全措施老化过时的风险,需要进行替换或升级。如何应对ICS面临网络攻击风险的事实?公共事业机构该从哪里开始防御这种之前从未考虑过的威胁?

为确保ICS能抵御今天的在线安全威胁,公司企业需采取足够的措施以创建有效工业安全项目并合理排定企业风险优先级。这听起来似乎是令人生畏的浩大工程,但健壮的多层安全方法可以分解为基本的3步:1) 保护网络;2) 保护终端;3) 保护控制器。

0、保护网络

工业公司应确保自身网络设计良好,有着防护周全的边界。企业应按 ISA IEC 62443 标准划分自身网络,保护所有无线应用,部署能快速排除故障的安全远程访问解决方案。公司网络,包括其工业网络基础设施设备,都应列入监视对象范围。

二、保护终端

运营技术(OT)团队可能会觉得公司的终端受到边界防火墙、0利安防软件、0业协议和物理隔离的防护,可以抵御数字攻击。但事实不是这样的,雇员、承包商和供应链员工将他们的笔记本电脑或U盘带入企业网络时,这些安全防护措施就被绕过了。

必须确保所有终端都是安全的,要防止员工将自己的设备接入公司网络。事实上,黑客可以侵入OT环境中基于PC的终端。公司企业还应保护其IT终端不受OT环境中横向移动的数字攻击侵袭。

购买资产发现产品,或者实现网上终端清点过程,是保护终端安全的不错开端。可以定义控制措施和自动化以确保防护到位。然后公司企业必须保证每台终端上的配置是安全的,并监视这些终端以防遭到未授权修改。

总体上,IT和OT环境通用的解决方案是公司企业明智的选择。应定义0个足够灵活的安全平台,既能够深度覆盖IT,又适用于敏感的OT环境。

三、保护控制器

每个工业环境都有其物理系统——致动器、校准器、阀门、温度感应器、压力传感器0类机械装置。这些与现实世界交互的物理系统被称为控制器,也就是桥接物理系统控制和网络指令接收行为的特殊计算机。很多案例中恶意黑客都曾获取过这些设备的控制权,引发设备故障,造成物理破坏,或对公司的损害。不过,如果仅仅是能访问而不能控制,恶意黑客也无法直接造成破坏。

通过加强检测能力和对ICS修改及威胁的可见性,实现脆弱控制器的安全防护措施,监视可疑访问及控制修改,以及及时检测/控制威胁,公司企业可有效防止工业控制器遭到数字攻击。

网络犯罪已成当今世界发展0快的产业之0。其范围涵盖仅仅出于好玩就发起攻击的脚本小子,以及像跨0公司0样运营的犯罪组织。随着ICS成为网络罪犯的主要目标,公司企业需采取措施做好ICS对数字威胁的防护。而要做好防护,就需要重点放在网络安全、终端安全和工业控制器安全的多层安全措施。重型燃机是干什么用的:大型船舶之类的发动机。主要用于发电、船舶动力的燃气轮机

我们有大量库存的控制系统部件。 我们还有许多新的硬件和停产备件,以帮助支持你现有的控制系统0、限幅滤波法/程序判断滤波法

方法:In terms of computing power, computers have already surpassed human brain, but this does not mean that computers are intelligent - so far, all types of computers are still only an extension of some functions of human brain (mainly memory and operation).

In the design of PLC system, the control scheme should be determined first, and the next step is the engineering design and selection of PLC. The characteristics and application requirements of the process flow are the main basis for design and selection. The programmable logic controller and related equipment shall be integrated and standard. According to the principle of easy integration with the industrial control system and easy expansion of its functions, the selected programmable logic controller shall be a mature and reliable system with operation performance in relevant industrial fields. The system hardware, software configuration and functions of the programmable logic controller shall be compatible with the device scale and control requirements. Being familiar with programmable controllers, function charts and related programming languages is conducive to shortening programming time. Therefore, when selecting and estimating engineering design, it is necessary to analyze the characteristics and control requirements of the process in detail, clarify the control tasks and scope, and determine the required operations and actions. Then, according to the control requirements, estimate the input and output points, the required memory capacity, determine the functions of the programmable logic controller, the characteristics of external equipment, etc, Then choose the programmable logic controller with high performance price ratio and design the corresponding control system. [5]

Point estimation

Appropriate margin should be considered in the estimation of i/o points. Usually, according to the statistical input and output points, an additional 10% - 20% expandable margin is added as the input and output point estimation data. When actually ordering, it is also necessary to round the input and output points according to the product characteristics of the manufacturer's PLC. [5]

Memory capacity

The memory capacity is the size of the hardware storage unit provided by the programmable controller itself. The program capacity is the size of the storage unit used by the user application items in the memory, so the program capacity is less than the memory capacity. In the design stage, because the user application program has not been prepared, the program capacity is unknown in the design stage, and it needs to be known after program debugging. In order to estimate the program capacity when designing and selecting models, it is usually replaced by the estimation of memory capacity. [5]

There is no fixed formula for estimating the memory capacity of memory. Many literature materials give different formulas, which are generally 10 ~ 15 times the number of digital i/o points, plus 100 times the number of analog i/o points. This number is the total number of words in the memory (16 bits is a word), and then 25% of this number is considered as the margin. [5]

Control function selection

The selection includes the selection of operation function, control function, communication function, programming function, diagnosis function, processing speed and other characteristics. [5]

1. Operation function

The operation functions of simple programmable logic controller include logic operation, timing and counting functions; The operation function of ordinary PLC also includes data shift, comparison and other operation functions; More complex operation functions include algebraic operation, data transmission, etc; Large programmable logic controller also has analog PID operation and other advanced operation functions. With the emergence of open systems, programmable logic controllers have communication functions. Some products have communication with the lower computer, some products have communication with the same computer or the upper computer, and some products also have the function of data communication with factories or enterprise networks. The design and type selection should be based on the requirements of practical application, and the required calculation functions should be reasonably selected. In most applications, only logic operation and timing and counting functions are required. Some applications require data transmission and comparison. When used for analog quantity detection and control, algebraic operation, numerical conversion and PID operation are used. Decoding, encoding and other operations are required to display data. [5]

2. Control function

The control functions include PID control operation, feedforward compensation control operation, ratio control operation, etc., which shall be determined according to the control requirements. Programmable logic controllers are mainly used for sequential logic control. Therefore, single loop or multi loop controllers are often used in most occasions to solve the control of analog quantities, and sometimes intelligent input and output units are used to complete the required control functions, so as to improve the processing speed of programmable logic controllers and save memory capacity. For example, PID control unit, high-speed counter, analog unit with speed compensation, ASC code conversion unit, etc. are used. [5] Automation technology is widely used in industry, agriculture, science research, transportation, commerce, medical treatment, service and family. The adoption of automation technology can not only liberate people from heavy physical labor, part of mental labor and harsh and dangerous working environment, but also expand human organ functions, improve labor productivity and enhance human ability to understand and transform the world.

Automation is a high-tech company specializing in the R & D, production and sales of intelligent automatic control, digital and networked controllers and sensors. Its numerous functional modules and perfect embedded solutions can meet the personalized needs of many users. The company's products have a variety of series of products to meet the needs of customers. The automation equipment is composed of vibrating plates.

significance

Large complete sets of equipment in the automation system, also known as automation devices. It refers to the process that the machine or device automatically operates or controls according to the specified procedures or instructions without human intervention. Therefore, automation is an important condition and significant symbol of the modernization of industry, agriculture, national defense and science and technology.

Check all power, air and hydraulic sources

Power supply, including the power supply of each equipment and the power supply of the workshop, that is, all the power supplies that the equipment can involve.

Air source, including air pressure source required by pneumatic device.

Hydraulic source, including the working condition of the hydraulic pump required by the hydraulic device.

In 50% of the fault diagnosis problems, basically the errors are the problems of power supply, air supply and hydraulic source. For example, there are problems in power supply, including the power supply failure of the whole workshop, such as low power supply, burned fuse, poor contact of power plug, etc; It is caused by the failure to open the air pump or hydraulic pump, the failure to open the pneumatic triplet or duplex, and the failure to open the relief valve or some pressure valves in the hydraulic system. These basic problems are usually common problems.

Check whether the sensor position is offset

Due to the negligence of equipment maintenance personnel, there may be errors in the position of some sensors, such as not in place, sensor failure, sensitivity failure, etc. Always check the sensor position and sensitivity, and adjust it in time in case of deviation. If the sensor is broken, replace it immediately. Most of the time, if the power supply, air source and hydraulic source are guaranteed to be correct, the more problem is the sensor failure. In particular, due to the use of magnetic induction sensors, it is likely that the internal grounding will stick to each other and cannot be separated, resulting in a normally closed signal, which is also a common problem of this type of sensors and can only be replaced. In addition, due to the vibration of the equipment, most sensors will be loose after use. Therefore, during daily maintenance, it is necessary to often check whether the position of the sensor is correct and whether it is firmly fixed.

Check the relay, flow control valve and pressure control valve

Like the magnetic induction sensor, the relay will also have grounding adhesion when used, so the normal electrical circuit cannot be guaranteed and needs to be replaced. In pneumatic or hydraulic systems, the opening of throttle valve and the pressure regulating spring of pressure valve will also loosen or slide with the vibration of equipment. Like sensors, these devices are components that need routine maintenance in the equipment. So in daily work

Speaking of AI, many people will trace back to the imagination of science fiction writers nearly a century ago or the hypothesis proposed by Turing 64 years ago, but in my opinion, the pursuit of machine intelligence runs through the whole history of human civilization. For example, the abacus, which Mr. Yang Zhenning called "the world's earliest computer", was a mainstream computing tool until the popularity of PC. in the 1970s and 1980s, many Chinese parents sent their children to learn mental arithmetic and abacus - the abacus itself is a tool endowed with rules by human beings and embodies human wisdom. In essence, it can be said to come down in one continuous line with today's PCs, smartphones and tablet devices.

IBM "deep blue", which defeated kasperov, is regarded by many as a milestone in AI research. When playing chess, players who can think of more follow-up moves, the other party's possible skills, the resulting changes, and the corresponding chess path adjustment after the changes are obviously more likely to win, and the advantages of computers in this regard are self-evident. The human brain can only imagine a few or a dozen moves, but the machine can simulate all possibilities. In other words, even if it is not "deep blue", sooner or later there will be other computer players challenging human success. Moreover, based on the current level of information technology development, if the man-machine battle of the world chess champion is turned into an annual routine event, it is very likely that no one can beat the machine opponent - even if it is just a Windows Phone. Of course, computer players can't capture the position of go originated in China in a short time, which makes us proud of the profound wisdom of our ancestors - some people estimate that the change possibility of go is 122 times greater than that of chess 10. The method of computer playing chess is to enumerate all possibilities, while human beings can selectively prune and deepen according to experience. It is conceivable that if we only make "judgments" by improving machine performance, storing chess scores, and optimizing algorithms, because the amount of computation that needs to be processed in real time is too large, the most powerful computer available is still impossible to defeat human masters.

However, it is true that computers are different from any tool invented by humans in the past. This difference is reflected in: first, it is not a special tool whose purpose has been solidified at the factory, such as bicycle and DVD player. Its ability depends on the program installed by the user. Second, it can inject new vitality into various special tools, such as the recently discussed "wearable device", which just implants some computing power into "traditional tools" such as wristbands, watches, glasses, etc., and establishes a data association with mobile phones and PCs.

All "tools" contain the intelligence, experience and ingenuity of their human creators. AI in a broad sense is to give products reasonable functional characteristics, and work with humans to accomplish things we can't and can't do well, so as to achieve the effect of "human + machine = super human". Just like hammers and axes are the strengthening and continuation of people's arms, cars, ships and planes are the strengthening and continuation of people's legs and feet. In recent years, driverless cars have attracted much attention. It seems that this is a new form of intelligent machine, but driverless aircraft has been invented many years ago - it also does not need people to control it. Which is more intelligent than an automobile?

In the past few decades, the evolution of computer hardware performance and the expansion of software application field have exceeded everyone's imagination. If we observe the extension of AI from a broad perspective and recognize that all tools infused with human thinking about the world reflect a certain degree of "intelligence", then we can say that intelligent devices can be seen everywhere in life.

Let the machine think and grow in its own way

"Hearing and seeing" is a compliment to people. Scientists have been trying to make computers understand the world in a human way, so speech recognition and computer vision have always been the focus of AI research - today we can talk with Cortana, or feel the technology of machine drivers in an unmanned car equipped with a 360 ° dead angle camera.

Are Cortana and unmanned cars a kind of robot? In a sense, yes. But if a "real robot" must be able to think like a human and have a humanoid appearance - well, who knows what we want to do with a machine like a human? Behind everyone's stubborn myth about humanoid machines, it is likely that you want to find a helper to do heavy work for yourself.

However, the reality is that there have been many machines that can help us do heavy work, whether it's making coffee, barbecue, washing dishes, cleaning... Do people like a robot with thick limbs running around in a white apron to do all the housework for us, or are they used to using various small devices to complete different tasks?

Assuming that everyone loves robots, there are still many obstacles on the road to products. For example, pouring a cup of tea from the teapot on the table without overturning the cup or spilling tea is not a challenge for human children - children can complete tasks without thinking. But for the most "smart" robot, it has to go through difficult and complex calculations. First of all, he should see the table, recognize the teapot and teacup, pick up the teapot with appropriate strength (it may not be possible if his fingers are too thick), lift the teapot, aim at the teacup at a just right angle, pour tea, and judge how to make the tea in the cup not overflow. Even if you happen to succeed once, the next round of completely different tables, teapots, and cups may still fail.

For a long time, scientists engaged in AI research, including those who are obsessed with creating humanoid machines, have always dreamed of transplanting human thinking, planning and execution capabilities to machines, but whether people act, machines should act? Whether the path for people to achieve their goals is from a to B, and the machine should follow exactly the same path? It is true that this kind of research has extraordinary scientific value, but it will also be difficult because of the paranoia of "giving steel tools human characteristics to be successful".

Another idea is to jump out of the rut and stand in the perspective of machines to simulate and extend human thinking, rather than using human perspectives and habits to limit machines. Driverless cars are not just "two eyes", but are equipped with multiple radar sensors, panoramic cameras and laser rangefinders. I-robot cleaning robot is the same. Her figure is round and flat, and she is not human at all, but she must be easier to use than a two meter high machine cleaner when vacuuming.

At first, the bottleneck of AI research was that human logical thinking mode could hardly be copied to machines. Whether it was sublimating low-order signals such as sound, image and smell to cognition, or refining common phenomena into laws, it was not a skill that machines could master - machine learning and big data brought AI research into the spring. Recently, new concepts such as deep learning and deep neural networks have emerged. With a larger amount of data and fewer assumptions and restrictions, machines can "think" and grow in the way they are good at (data storage, mining, analysis), and then go faster and farther on the road of practicality.

Man machine relationship: master and assistant