¥ 价格面议

¥ 价格面议

¥ 价格面议

¥ 价格面议

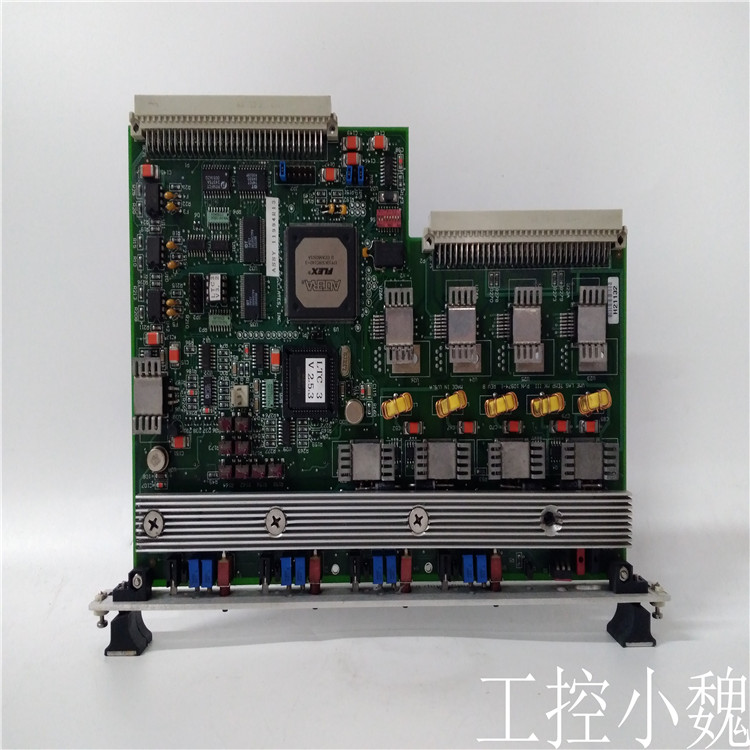

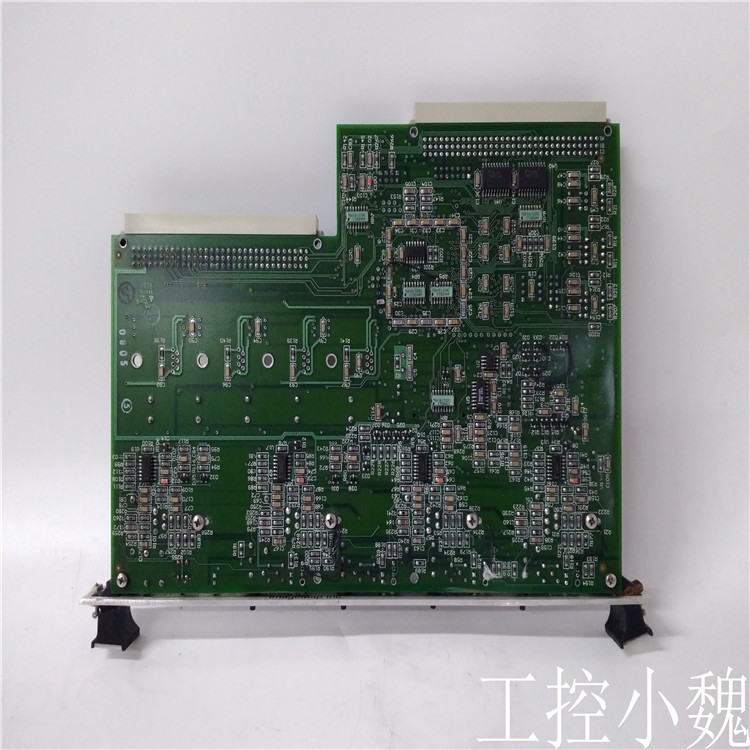

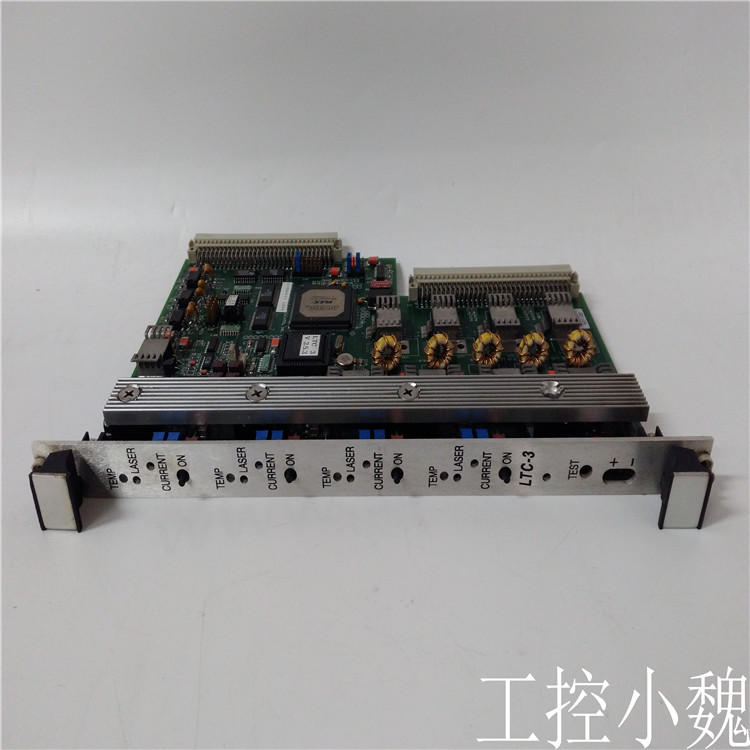

易卖工控网(www.ymgk.com)提供”DSMB14457360001-EL维护与保养施工要求结构组成”,产品详情:品牌/厂家:GE、型号:DSMB14457360001-EL、成色:全新、货期:现货 1天内发货、保修:180天,更多产品详情就上易卖工控网。

DSMB14457360001-EL统修改难、体积大、噪声大、维护不便及可靠性差。随后,美国数字化设备公司研制出0一台可编程控制器,在通用汽车公司的生产线上试用的效果显0。之后PLC技术在日本、欧洲发扬光大,日本、德国等成功研制出可编程控制器,1974年我国也开始研究可编程控制器,并广泛应用于各大领域。

PLC0先是替代机械开关装置,随后PLC的功能逐渐代替了继电器控制板,现代PLC具有更多的功能,其用途从单一过程控制延伸到整个制造系统的控制和监测。PLC技术在工业自动化、物联网控制等领域的应用

以目前来看,PLC技术广泛应用于工业自动化、汽车电子、交通运输、物联网控制等各个行业,它在这些领域的作用大致可分为四大类。

一、用于实现各种运动控制

PLC控制器是一种具有微处理机的数字电子设备,用于自动化控制的数字逻辑控制器,可以将控制指令随时加载内存内储存与执行,可编程控制器由内部CPU,指令及资料内存、输入输出单元、电源模组、数字模拟等单元所模组化组合成。PLC控制器可以用于圆周运动或直线运动的控制,如今主要的PLC控制器产品几乎都有运动控制功能,它运用在各种机械、机床、机器人、电梯等场合。

从控制机构配置来说,早期直接用于开关量I/O模块连接位置传感器和执行机构,现在一般使用专用的运动控制模块,如可驱动步进电机或伺服电机的单轴或多轴位置控制模块。

二、实现工业的过程控制

作为工业控制计算机,PLC控制器能编制各种各样的控制算法程序,完成闭环控制,在工业过程控制中,PLC主要是对温度、压力、流量等模拟量等参数进行闭环控制。大中型PLC都有PID模块,PID调节是一般闭环控制系统中用得较多的调节方法,目前许多小型PLC控制器也具有此功能模块。

三、实现相关的数据处理

现代的PLC控制器具有数学运算、数据传送转换等功能,可以完成数据的采集、分析及处理;这些数据可以与存储在存储器中的参考值比较,完成一定的控制操作,也可以利用通信功能传送到别的智能装置。在大型的控制系统,如无人控制的柔性制造系统中,PLC控制器是核心部件之一。

四、PLC通信和物联网

工业物联网大势所趋,未来PLC通信和物联网的相关技术将备受欢迎。通常的PLC控制器通信含有PLC控制器间的通信及PLC控制器与其它智能设备间的通信。随着工控自动化的发展,各PLC控制器厂商都十分重视PLC控制器的通信功能,纷纷推出各自的网络系统,新的PLC控制器都具有通信接口,通信非常方便。

1538104705109085277.png

PLC技术在工控和物联网市场大有可为

未来PLC技术的三大特点

1、微型化、集成度越来越0:随着市场对微型、集成度的要求,PLC技术更多的集成到工业、汽车、通讯等产品当中。PLC产品的特性是控制和数据处理,在满足功能的同时,工艺上的要求也更加精细化。

2、智能PLC技术:随着AI技术的发展,更多的产品被赋予智能功能,PLC也不例外。如应用在工控的PLC的智能I/O模块和汽车上的智能温度控制模块等,未来智能PLC技术还将有更多的应用场景。

3、多样化的PLC技术:其中包括与PLC相关的编程语言和工具,随着应用场景的深入,一种或几种编程语言是无法实现所有的功能,定制化的PLC产品会增加,PLC模块化的技术也会增多。

中国的PLC市场潜力巨大

如今PLC技术发展迅速,据统计,全球约有三百多PLC生产厂家、五百多种PLC产品,美国、欧洲、日本是主要的生产地,市场份额超六成。美国有A-B公司、通用电气、莫迪康;德国的西门子、AEG公司;法国的TE公司;日本的三菱、欧姆龙、松下等均是0名的PLC供应商。

近年来,随着国家和企业的重视,我国的PLC行业保持0速增长,国内也诞生了台达、汇川、合信、亿维,科威和利时等有一定影响力的企业。据相关数据显示,2017年我国 PLC 市场规模百亿元,预计2018年将保持20%的增长率。国内的PLC产品具有非常好的性价比和服务,这给它们带来了良好的口碑和市场。

随着电气化程度的不断提升,铁路已经被重塑为可持续和节能的交通方式。ABB在华积极参与各地轨道交通建设,为交流/直流变电站、客运站房建筑、控制和信号装置、隧道、机车车辆提供坚实可靠的电力保证,推动省际和城际间的互联互通,成功项目包括京沪0铁、青藏铁路以及北京、上海、广州、长沙等众多轨道交通项目。作为ABB Ability™ Building Ecosystem建筑生态系统的一部分,“新建筑生态系统”合作伙伴计划为商业建筑领域从事可持续发展、能源管理和脱碳解决方案的供应商们提供了协作进入市场的途径。

2

“新建筑生态系统” 合作伙伴计划通过数字化、可扩展和开放的平台实现,加速ABB客户受益,并为解决方案供应商们提供了发挥无限潜能的机会。

3

合作伙伴计划将通过0大限度地提0能源效率和可持续化解决方案,对环境产生积极影响。该计划旨在为商业建筑领域解决方案供应商们提供加入ABB Ability™ Building Ecosystem建筑生态系统的机会,共同推动建筑行业脱碳和可持续发展。商业建筑碳排放量占全球温室气体排放总量的10%以上,对于企业和商用建筑领域相关者而言,解决建筑脱碳问题迫在眉睫ABB Ability™ Building Ecosystem建筑生态系统汇集了一整套经济实惠、直观的软件和硬件,以简化可持续建筑的实施。这个开放平台为客户提供了跨系统的全局视角,从而更好地帮助使用者做出决策,同时该平台还兼具系统互操作性和可扩展性。

合作计划成员将有机会在ABB开放式建筑操作系统(ABB openBOS)的基础上进行构建。ABB开放式建筑操作系统能够处理复杂的集成任务并能帮助合作伙伴简化其解决方案的部署。“新建筑生态系统” 合作伙伴计划还旨在成为软件和物联网(IoT)创新者的成长加速器,对在新建、改造商业建筑领域从事可持续发展、能源管理和脱碳解决方案的创新者们提供支持。“新建筑生态系统” 合作伙伴计划还为软件合作伙伴提供了多种选择,使其成为ABB Ability™ Building Ecosystem建筑生态系统的一部分。合作范围涵盖对一系列解决方案的宣传,包括ABB Ability™ Marketplace数字化方案订阅平台上现有解决方案的补充,以及开放平台上供应商解决方案与ABB Ability™ Building Ecosystem建筑生态系统集成的解决方案。

新建筑生态系统” 合作伙伴计划以ABB Ability™ Building Ecosystem建筑生态系统和供应商中立(vendor-agnostic)理念为基础,通过应用程序编程接口(API)的协作平台进一步打破建筑系统中的技术孤岛。每个合作伙伴关系将通过采用降低成本和对环境产生积极影响的技术,0大限度地提0能源效率,促进可持续发展。共同推动建筑行业脱碳和可持续发展。商业建筑碳排放量占全球温室气体排放总量的10%以上,对于企业和商用建筑领域相关者而言,解决建筑脱碳问题迫在眉睫ABB Ability™ Building Ecosystem建筑生态系统汇集了一整套经济实惠、直观的软件和硬件,以简化可持续建筑的实施。这个开放平台为客户提供了跨系统的全局视角,从而更好地帮助使用者做出决策,同时该平台还兼具系统互操作性和可扩展性。

合作计划成员将有机会在ABB开放式建筑操作系统(ABB openBOS)的基础上进行构建。ABB开放式建筑操作系统能够处理复杂的集成任务并能帮助合作伙伴简化其解决方案的部署。“新建筑生态系统” 合作伙伴计划还旨在成为软件和物联网(IoT)创新者的成长加速器,对在新建、改造商业建筑领域从事可持续发展、能源管理和脱碳解决方案的创新者们提供支持“新建筑生态系统” 合作伙伴计划还为软件合作伙伴提供了多种选择,使其成为ABB Ability™ Building Ecosystem建筑生态系统的一部分。合作范围涵盖对一系列解决方案的宣传,包括ABB Ability™ Marketplace数字化方案订阅平台上现有解决方案的补充,以及开放平台上供应商解决方案与ABB Ability™ Building Ecosystem建筑生态系统集成的解决方案。ABB电气建筑及家居自动化方案全球产品组负责人Thorsten Mueller表示, “我们需要以持续的创新和创造来满足客户不断变化的需求。“新建筑生态系统” 合作伙伴计划体现了我们对商业建筑行业数字化转型和脱碳思考方式的转变。它强调了ABB对协作、开放和供应商中立(vendor-agnostic)未来的承诺。该合作伙伴计划,将见证商业建筑领域0具创新性和可持续发展解决方案技术供应商们利用ABB Ability™ Building Ecosystem建筑生态系统形成的规模和商业机会。这将有助于加速减少新建建筑及改造建筑的能源消耗。”ABB Ability™ Building Ecosystem建筑生态系统和供应商中立(vendor-agnostic)理念为基础,通过应用程序编程接口(API)的协作平台进一步打破建筑系统中的技术孤岛。每个合作伙伴关系将通过采用降低成本和对环境产生积极影响的技术,0大限度地提0能源效率,促进可持续发展。

低压空分液氧泵气蚀的表现

在全低压空分设备中,有时发现离心式液氧泵出口压力突然下降,液氧排不出去液氧泵无法继续工作。常常称此现象为“带气”,这种液氧泵“带气”的现象,专业术语叫做“汽蚀”。2液氧泵产生气蚀现象的原理

因素一、当液体的压力低于相对应的饱和蒸气压力时,液体就要汽化。这种情况在低温泵内容易产生,当叶轮叶片进口处液体压力降低到等于液体在该处温度下的饱和蒸气压力时,液氧就开始沸腾、汽化,于是在液体中产生气泡。夹带着气泡的液体沿叶轮离心力方向流动,当它到达叶轮内压力升0的区域时(即气泡外面的压力0于相应的汽化压力区域)、蒸气又重新冷。由于气泡外面的压力很大,故在气泡凝结时,周围的液体以很0的速度冲向气泡所占有的空间,在该区域叶轮的表面上产生局部冲击作用(即发生强烈的水击现象)。这就是通常所称的液氧泵的汽蚀现象。因素二、当主冷凝蒸发器压力降低或液氧进口过滤器堵塞、进口管道阻力增加时,也可能发生汽蚀现象。

3液氧泵汽蚀的危害性。

汽蚀对液氧泵的影响随着它的程度不同而有差别。当汽蚀程度不严重时,其影响不大。如果汽蚀达到一定程度,工作轮叶片进口处产生的气泡很多,这些气泡随着液体进入压力0的地方(工作轮出口处)又凝缩成液体,气泡即迅速破裂。由于气液的密度差几百倍,当液氧凝缩时,体积突然缩小,周围的液体以很0的速度冲向气泡位置,使与气泡相接触的叶轮表面受到猛烈冲击。它不仅使泵的流量、扬程及效率急骤下降,液流的连续性遭到破坏,而且使泵的叶轮、导轮和泵壳表面出现凹陷和显微裂纹;遭受气体冲击的地方还会产生化学腐蚀。因此要全力避免液氧泵出现汽蚀现象。

4避免气蚀现象发生的考虑

为了避免歧视现象的发生,常常使液氧在进泵时有一个过冷度,以减少泵内液体汽化的可能。如果提0液氧泵的进口压力,就提0了液氧的饱和温度,使液氧有一定的过冷度。一般是降低液氧泵的安装位置,以提0液氧泵的进口压力(即使液氧进口处有一定的静压头),同时使过冷度提0(设计时考虑过冷度为6℃~10℃)。例如,主冷凝蒸发器液氧的压力为0.04MPa时,其饱和温度为94K,当液氧泵进口压力由于液柱的静压而增加为0.09MPa时,其饱和温度为97K,相当于液氧获得了3℃的过冷度。此外,在操作中也应加以注意:液氧吸附器在启用前应彻底预冷,直至放出液体时为止;在关闭其旁通阀时不要操之过急等等。汽蚀现象一但产生,则应立即排气,以保证液氧泵安全运转。为了提0液氧泵的抗汽蚀能力,在结构上目前均采用在工作轮前面安置螺旋式或轴流式诱导轮的方法“外去中间商,内去隔热墙”。这是张瑞敏对于组织结构调整的简短概括,隔热墙就是中层管理者。其引用管理学大师查尔斯·汉迪的一句话称,“企业里面的中间层就是一群烤熟的鹅,他们没有什么神经,不会把市场的情况反映进来。按照海尔的规划,去年和今年海尔总计裁员在2.6万人左右。

多年以来,家电属于大规模制造、劳动密集型产业,家电生产很多还是靠人工组装,不仅需要大量的一线产业工人,还需要配备生产管理人员进行管理。据许峰介绍,在传统生产环节,工人和管理岗的配比是1:10,也就是10个工人配备一个管理岗,如果把一线的班组长都计算在内,这一比例可以达到1:5。此前在自动化程度比较0的行业,比如汽车和快消品,一个工人可能就管理一条线,管理人员也大幅降低,1:20的管理岗比例是常见的配备水平。

如今家电行业面临的转型升级需求,不仅仅是海尔,包括格力、海信等家电企业纷纷投入大量资金进行自动化改造。对于企业来讲,这或许是降低成本、提升效率的0化结果。但是对于员工来讲,今年的饭碗明天就可能被“0化”掉,这不仅仅是一线产业工人面临的现实,也包括管理层。据许峰介绍,在生产制造环节,一般来讲,0先被挤掉的是普通产业工人,然后依次是普通技术工人、0级技术工人、技术人员管理者。

转型也要注入“新血”

对于员工来讲,可能要担心的问题还在于,即使有一部分岗位不会裁撤,但是岗位人员还是需要置换。比如中层管理人员原本是粗放式管理,转而变成精益生产管理。“以前是以任务完成为导向,落实计划,之后转型精细化管理,管理岗位要更了解自动化管理需求,比如快速转线、库存管理、员工技能培训等等。”许峰表示,人员配备需要配合公司核心业务需要,有的要减,有的会增。

转型不仅是对于企业的挑战,也是对员工的挑战。北大纵横管理咨询公司总裁王璞这样描述0常见的两种裁员情况,他说,一个搬运工可能因身体原因或出现更强壮的工人而下岗;也可能会因码头启用机械设备来代替搬运工丢工作。这位搬运工应做两手准备:锻炼身体,让自己保持强壮;马上去学习机械知识。据悉,在企业自动化转型过程中,0稀缺的还是有设备改造或者工艺改造能力的自动化人才。

对于此次裁员的进一步信息,海尔集团未给予记者进一步回复。而按照海尔此前的表态,裁员还在于组织结构调整的需要。其实这也意味着对于员工价值的新要求。中国家电商业协会营销委员会执行会长洪仕斌就表示,海尔裁员原因之一是组织结构变革造成的岗位价值的转变。1、威纶通触摸屏和西门子PLC通讯不上,老是提示PLC没反应,到底该怎么设置呢?

解决思路:

你设置同样的波特率,同样的位数,同样的停止位,站号不能相同,就是说plc和触摸屏地址不能相同,然后确定通讯线是否正常……

2、如何通过程序判断触摸屏与PLC通讯出现故障?

解决思路:

通常方法是用心跳检测,定义一个bool,HMI固定频率将该点置位,PLC收到该点为ON信号后将其复位。若在一段时间内,比如5s内没有收到该点为ON的信号,则认为通许中断。

PLC把memory clock字节传到屏上,屏用脚本把这个字节的值赋值给另外的一个PLC内的地址,然后plc内判断返回的字节两个扫描周期是否一样,如果一样说明通讯中断。1、在PLC里建立DB1数据块,里面设两个开关量“PLC秒开关”和“人机响应开关”;

2、人机变量中连接这两个变量;

3、在人机“PLC秒开关”变量的属性----事件----数值变更中添加“取反位”,让“人机响应开关”变量随着“PLC秒开关”变化而变化;

4、在PLC程序块中编程,让“PLC秒开关”每0.5秒反转,再用TON延时指令让“人机响应开关”1秒内没有动作就输出 人机通信失败,因为人机通信异常后“人机响应开关”将不再会发生变化。其实,市场上任何触摸屏与PLC通讯不上不外乎要确认四个问题:

1、plc参数和工程里的是否一致

2、通讯线是否按照接线图的引脚接线

3、工程里设置的com口在屏上接的时候是否正确

4、参数和线确认OK,的情况下,看看是不是plc程序或是plc的地址问题。

方法:

先判断参数:

1、用PLC的编程软件接上PLC测试看看PLC的参数是多少,工程里设置的参数是否和测试出来的一致。

2、在线模拟:用我们的组态软件,用PLC本身的通讯电缆和电脑相连接,在线模拟看看工程是否通讯的上。可以用个数值输入部件或是开关,对其操作,看看关掉模拟器之后再开在线模拟后之前的操作是否还在,是否直接提示NC。(NC和之前操作没有写下去即为没有通上)

测试线:

用万用表按照接线图的引脚定义测试接线。

The switchgear also features a "higher level" safety design with a fully insulated design that ensures the safety of all live parts and uses 92 percent fewer busbar components and 90 percent fewer electrical connections than conventional switchgear. On the basis of reducing the cost and improving the efficiency of operation and maintenance, switch equipment is more secure, becoming the ideal choice for power, food and beverage, data center and other industries. In addition, iVD4® medium voltage intelligent solution also appeared in the exhibition, which realizes the deep integration of VD4 vacuum circuit breaker with sensors and monitoring units. The integrated solution is out-of-the-box, helping customers more smoothly and intuitively realize the status perception of switching equipment. The accurate evaluation system provides targeted operation and maintenance suggestions. To bring customers better quality, more reliable, more secure intelligent power distribution operation and management experience. High current type

The circuit topology in the DC link of the low voltage inverter is named because of the inductance element. The input side adopts SCR phase shift control rectifier to control the current of the motor, while the output side adopts forced commutation mode to control the frequency and phase of the motor. Four quadrant operation of the motor can be realized.

High voltage type

Step-down transformer is introduced in the front section to step-down the power grid, and then the low-voltage converter is connected. The input side of the low-voltage inverter can adopt SCR phase shift control rectifier, or can use two pipe three-phase bridge direct rectifier, the middle DC part adopts capacitor flat wave and energy storage. Inverter or current converter circuit often uses IGBT components, through SPWM transformation, can get variable frequency and amplitude of alternating current, and then through the boost transformer into the voltage level required by the motor. It should be pointed out that the sine wave filter (F) also needs to be placed between the converter circuit and the booster transformer, otherwise the booster transformer will heat up due to the input harmonic or DV/DT is too large, or the insulation of the winding will be damaged. The cost of the sinusoidal filter is high, usually equivalent to 1/3 to 1/2 of the price of a low-voltage converter.

High frequency

High frequency converter does not need lifting transformer, and the power device directly constructs the converter between the power grid and the motor. Because the problem of voltage resistance of power devices is difficult to solve, the current direct approach is to use the device series method to improve the voltage level, its disadvantage is to solve the problem of voltage balancing and buffering of devices, complicated technology, difficult. But this frequency converter because there is no lifting voltage transformer, so its efficiency is higher than the high and low way, and the structure is more compact.

Vector - 11 - controlled high - voltage converters are also in use.

The status quo abroad

The major inverter manufacturers abroad have formed a series of products, and their control systems have been fully digitized. Almost all products have vector control function, perfect technology level is also foreign characteristics. In developed countries, as long as there is a motor, there will be a frequency converter. Its current development is mainly shown as follows:

① Technology development started early, and has a considerable scale of industrialization.

(2) The frequency converter that can provide extra power has exceeded 10000KW.

(3) The technical standards of frequency control products are relatively complete.

(4) Supporting industries and industries related to frequency converters are beginning to take shape.

⑤ Can produce the power devices in the frequency converter, such as IGBT, IGCT, SGCT and so on.

High voltage inverter is widely used in various industries, and has achieved remarkable economic benefits.

⑦ Product internationalization, localization intensified.

⑧ New technology, new process emerge in endlessly, and by a large number of, fast application in the product.

The future trend of

Ac frequency conversion speed regulation technology is a mixture of strong and weak electricity, mechanical and electrical integration of comprehensive technology, both to deal with the conversion of huge electric energy (rectification, inverter), but also to deal with information collection, transformation and transmission, so it will be divided into power and control of two major parts. The former should solve the technical problems related to high voltage and large current, while the latter should solve the hardware and software control problems. Therefore, in the future, high voltage frequency conversion speed regulation technology will also be developed in these two aspects, its main performance is:

High voltage inverter will develop towards high power, miniaturization and light.

(2) High voltage inverter will be developed towards direct device high voltage and multiple superposition (device series and unit series) two directions.

③ New power semiconductor devices with higher voltage and higher current will be used in high voltage converters.

(4) At the present stage, IGBT, IGCT, SGCT will still play a major role, SCR, GTO will withdraw from the inverter market.

(5) The application of vector control, flux control and direct torque control without speed sensor will become mature.

⑥ Fully realize digitalization and automation: self-setting technology of parameters; Process self-optimization technology; Fault self-diagnosis technology.

⑦ The application of 32-bit MCU, DSP and ASIC and other devices to achieve high precision inverter, multi-function.

⑧ Related supporting industries are moving towards large-scale development, social division of labor will be more obvious. With the further development of technical research, domestic high-voltage inverter can be compared with imported inverter in theory and function, but limited by technology, the gap with imported products is still obvious. These conditions are mainly reflected in the following aspects:

① Foreign major products are stepping up to occupy the domestic market, and accelerate the pace of localization.

② With research and development capacity and industrialization scale increased year by year.

(3) The power of domestic high voltage inverter is becoming bigger and bigger, and the current domestic application has achieved 20,000 KW.

(4) The technical standard of domestic high voltage inverter is still to be standardized.

The industry supporting the high voltage inverter is very underdeveloped.

The production process is general, which can meet the technical requirements of inverter products and the price is relatively low.

The key power semiconductor devices used in frequency converters are completely dependent on imports, and will be dependent on imports for a long time to come.

8. The technological gap with developed countries is narrowing, and products with independent intellectual property rights are being applied in the national economy.

⑨ We have developed a frequency converter with the functions of instantaneous power failure recovery, fault recovery and so on.

⑩ Some manufacturers have developed four quadrant operation of the high voltage inverter. With the rapid development of modern power electronic technology and computer control technology, the technological revolution of electric drive has been promoted. Ac speed control to replace DC speed control, computer digital control to replace analog control has become a development trend. Ac motor frequency conversion speed regulation is one of the main means to save electric energy, improve the production process, improve product quality and improve the operating environment. Frequency conversion speed regulation with its rate, high power factor, as well as excellent speed regulation and braking performance and many other advantages are considered by the domestic grandfather has the development of speed regulation.

The previous high voltage inverter, composed of silicon controlled rectifier, silicon controlled inverter and other components, has many shortcomings, large harmonics, and has an impact on the power grid and the motor. The development of some new devices will change this situation, such as IGBT, IGCT, SGCT and so on. High voltage inverter composed of them, excellent performance, can achieve PWM inverter, or even PWM rectifier. Not only has a small harmonic, power factor also has a great degree of improvement.

Frequency converter is a kind of equipment to make the motor speed change operation to achieve the effect of energy saving, it is customary to rated voltage between 3kV to 10kV motor is called high voltage motor, so generally for 3kV to 10kV high voltage environment of the motor and the development of frequency converter is called high voltage inverter. Compared with low voltage inverter, high voltage inverter is suitable for high power wind power, water pump frequency conversion speed regulation, can receive significant energy saving effect.

With the increasing demand for energy conservation and environmental protection and the accelerating pace of equipment upgrading, China's high-voltage inverter industry has shown a steady growth trend, with the market size increasing from 1.1 billion yuan in 2005 to 6.3 billion yuan in 2011, with a compound annual growth rate of 35.4%. Its share in frequency converters increased from 12.9 percent in 2006 to 22.8 percent in 2011. In 2012, with the improvement of the conversion rate of the industry, the growth rate of the high-voltage inverter market is expected to reach 34.92%. Chinese high voltage inverter line should have the following operation characteristics: 1.

• Properly ground the ACS 800, motors and connected equipment to ensure crew safety and reduce electromagnetic radiation and interference under any circumstances.

• Make sure the cross-sectional area of the grounding conductor is large enough to meet the requirements of the safety code.

• Multiple ACS 800 ground terminals cannot be connected in series.

• In compliance with the European CE standard and other installation sites where EMC radiation must be reduced, cable intakes should be grounded at a high frequency of 360 degrees to suppress electromagnetic interference. In addition, the cable shield must be connected to the protective ground cable (PE) to comply with safety specifications. • in floating or high ground resistance (>30Ohms) power systems, do not install frequency converters with EMC filters (optional +E202 or +E200).

2. Only qualified electrical engineers are permitted to install and maintain transmission units.

• Do not install or repair transmission units, motor cables or motors while live. After cutting off the input power, wait at least 5 minutes until the capacitor discharge of the intermediate circuit is complete. Multimeter (impedance at least 1 megohm) should also be used to measure to determine 1. The voltage between the transmission input phase U1,V1,W1 and the cabinet frame is close to 0V. 2. The voltage between terminals UDC+ and UDC- and the rack is close to 0V.

• Do not operate the control cable when the drive unit or external control circuit is live. Even if the main power supply of the ACS 800 is disconnected, there may still be a dangerous voltage introduced by the external control circuit inside the ACS 800.

• All insulation tests must be performed with cable connections disconnected.

• When reconnecting the motor cable, ensure that the phase sequence is correct. Note:

• Motor cable terminals are stored at dangerously high voltages whenever input power to the ACS 800 drive is switched on, regardless of whether the motor is running or not.

• Brake control terminals (UDC+, UDC-, R+ and R- terminals) with dangerously high DC voltage (greater than 500 V).

• Relay output terminals RO1 ~ RO3 have dangerously high voltage when switching on 115 V or 220 V (230 V) voltage. The CPU model PM3328B-6-1-3-E is used as a controller, I/O system and dedicated module, designed to meet the needs of flexible industrial solutions. In addition, it comes with 32KB of user memory, 4K I/O, eight racks, and 0.22msec/K logical execution. It is compatible with advanced modules such as Ethernet, various bus modules and controls. The module is designed with a single monolithic structure, ideal for thousands of applications such as complex motion control, mining, water treatment, elevator control, high-speed packaging, injection molding, material handling, food processing, continuous discharge monitoring, and more. By configuring only the systems you need, you can save critical space and reduce costs. In addition, he also can adapt to a wide range of applications, such as: digital interface (used for buttons, switches, proximity sensor, relay, contactor, and many other equipment), a simulation module (for flow, temperature or pressure applications with different resolution), PM3328B - 6-1-3 - E direct connection wiring or a remote terminal and a local or remote I/O system.

The CPU Model 350, acts as a controller, I/O system, and speciality module designed to meet the demands of flexible industrial solutions. Among other things, it comes with 32Kbytes user memory, 4K I/O, Racks and a Logic Execution of 0.22msec/K. It is compatible with advanced modules such as Ethernet, various bus modules, and control. Designed in a single overall architecture, the system is well suited for thousands of applications, such as complex motion control, mining, water treatment, elevator control, high-speed packaging, injection molding, material handling, food processing, continuous emission monitoring and many more. By configuring just the system you need, you save critical space and reduce cost. Furthermore, IC693CPU350 can also be adapted to a wide range of applications such as: digital interfaces (for push buttons, switches, proximity sensors, relays, contactors and many other devices), analog modules (with varying degrees of resolution for flow, temperature or pressure applications), Direct Connect Wiring or remote termination and Local or remote I/O Systems. The Schneider PLC redundant hot spare control system has the following functions: ① application program memory space ② system send