¥ 价格面议

¥ 价格面议

¥ 价格面议

¥ 价格面议

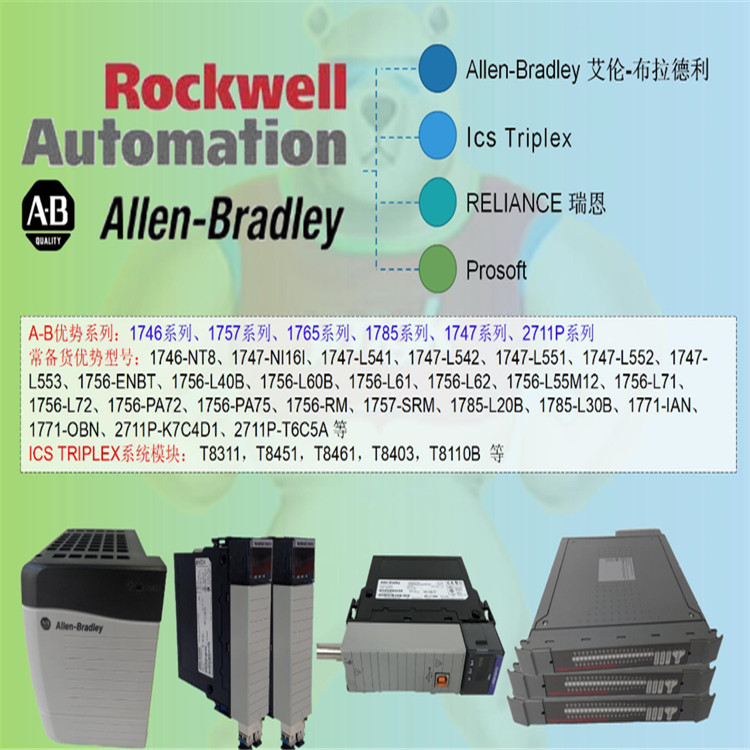

易卖工控网(www.ymgk.com)提供”ST701AHITR402804R市场现状行情发展前景处理设施”,产品详情:品牌/厂家:AB、型号:ST701AHITR402804R、成色:全新、货期:现货 1天内发货、保修:180天,更多产品详情就上易卖工控网。

ST701AHITR402804R场现状行情发展前景处理设施探寻世界知名建筑,ABB从未止步。欢迎大家关注《建筑是凝固的音乐》系列短片,随时了解更多建筑故事,与ABB一起环游世界。机器视觉技术,是一门涉及人工智能、神经生物学、心理物理学、计算机科学、图像处理、模式识别等诸多领域的交叉学科。机器视觉主要用计算机来模拟人的视觉功能,从客观事物的图像中提取信息,进行处理并加以理解,0终用于实际检测、测量和控制。 什么是工业相机? 工业相机是机器视觉系统中的一个关键组件,其本质功能就是将光信号转变成有序的电信号,相当于机器视觉系统的“眼睛”。相比于传统的民用相机(摄像机)而言,工业相机(摄像机)具有高图像稳定性、高传输能力和高抗干扰能力等,市面上工业相机大多是基于CCD(Charge Coupled Device)或CMOS(Complementary Metal Oxide Semiconductor)芯片的相机。 CCD,电荷藕合器件图像传感器。它使用一种高感光度的半导体材料制成,能把光线转变成电荷,通过模数转换器芯片转换成数字信号,数字信号经过压缩以后由相机内部的闪速存储器或内置硬盘卡保存,因而可以轻而易举地把数据传输给计算机,并借助于计算机的处理手段,根据需要和想像来修改图像。

CMOS,互补性氧化金属半导体。和CCD一样,同为在数码相机中可记录光线变化的半导体。CMOS的制造技术和一般计算机芯片没什么差别,主要是利用硅和锗这两种元素所做成的半导体,使其在CMOS上共存着带N(带–电) 和 P(带+电)级的半导体,这两个互补效应所产生的电流即可被处理芯片纪录和解读成影像。

工业相机的作用 工业相机一般安装在机器流水线上代替人眼来做测量和判断,通过数字图像摄取目标转换成图像信号,传送给0用的图像处理系统,图像系统对这些信号进行各种运算来抽取目标的特征,进而根据判别的结果来控制现场的设备动作。 随着国内机器视觉行业的迅猛发展,机器视觉系统的重要组件,工业相机也同样得到了巨大的发展。数字工业相机对被摄物的大小没有限制,根据镜头的条件,既可以拍摄一般物质,也可以用于显微镜摄影。目前,工业相机的主要用途包括以下几个方面: (1)在开发产品和验证产品等:如开发金属材料及树脂材料时,用来观察材料受到冲击时内部裂纹产生的方向、状态等,可用来分析材料被破坏时物质的结构,及电子产品的工业在线检测等。 (2)包装和标签行业的印刷过程中,能够实时检测到高速印刷中细微的缺陷,以便采取措施,减少损失。常见的缺陷如划痕、灰尘、漏印、墨痕、褶皱等都可被检测出来,提高投资回报,减少废品支出,提高了客户满意度和信任度。 (3)其他领域:如机器视觉、科研、军事科学、航空航天等众多领域,尤其是在智能交通行业:超速抓拍,闯红灯电子警察、高速路口、卡扣收费等交通行业也得到了良好的使用。 工业相机的分类 企业在实际选购和使用工业相机之前,00需要确定的就是相机的类型。下面是按照不同的行业标准进行的工业相机分类。 (1)芯片类型 分为CCD相机、CMOS相机; (2)传感器的结构特性 分为线阵相机、面阵相机; (3)按照扫描方式 分为隔行扫描相机、逐行扫描相机; (4)分辨率大小 分为普通分辨率相机、高分辨率相机; (5)输出信号方式 分为模拟相机、数字相机; (6)输出色彩 分为单色(黑白)相机、彩色相机; (7)输出信号速度 分为普通速度相机、高速相机; (8)响应频率范围 分为可见光(普通)相机、红外相机、紫外相机等。 工业相机为什么会丢帧? 选择合适的相机也是机器视觉系统设计中的重要环节,相机的选择不仅直接决定所采集到的图像分辨率、图像质量等,同时也与整个系统的运行模式直接相关。设计不良的驱动程序或工业相机硬件可能会造成丢帧,其原因就是资料通道的堵塞,无法及时处理,所以新的图像进来时,前一张可能被迫丢弃,或是新的图像被迫丢弃。要解决这问题,需要设计者针对驱动程序与工业相机硬件资料传输的每个环节进行精密的设计。 智能相机与工业相机 智能相机(Smart Camera)并不是一台简单的相机,而是一种高度集成化的微小型机器视觉系统。它将图像的采集、处理与通信功能集成于单一相机内,从而提供了具有多功能、模块化、高可靠性、易于实现的机器视觉解决方案。同时,由于应用了0新的DSP、FPGA及大容量存储技术,其智能化程度不断提高,可满足多种机器视觉的应用需求。 工业相机与智能相机的应用场合相差不大,但使用上却有很大的差别,工业相机需要外接控制器,需要0业性比较强的软件人员来进行编程,可应对各种复杂的检测要求,而智能相机则内置简单实用的调试工具,可以独立工作而不需要外接控制器,操作简单,容易上手。ABB LGR 分析仪的优势之一在于其稳定性和便携性,这两个关键特点解释了为什么许多客户将它们用于各种机载操作。不少机载飞行监测温室气体的科学研究成果已在一些科学家撰写的论文中发表。

相比CRDS技术,LGR 0利的0四代离轴积分腔输出光谱技术(OA-ICOS)不需要实现亚纳米级的光路对准,且不需要昂贵且复杂的减振或外部压力稳定方案,即可在飞行期间提供出色的数据。ABB基于北斗卫星导航系统的ABB Ability™天然气泄漏检测车载版与无人机版解决方案,在往届中国进口博览会上成功0发后,已为中国众多城市提供了高精准燃气管网检测服务。去年,ABB又推出了“ABB0域多维立体温室气体监测管家系统”,基于多种光学吸收原理,广泛应用于从太空到陆地、从固定污染源到大气环境站、从点式到线面测量,提供 “天-地-太空” 高密度立体监测技术,精准量化来自城市、工业、基础设施和农业等各类温室气体的源汇贡献,为国家“双碳”目标落地提供告价值的基础数据与领0的技术支撑在机载式应用中,除了此次珠峰科考所采用的直升机载温室气体监测解决方案外,ABB在2018年推出了0球0一款高精度轻型无人机载温室气体分析系统。

ABB GAL133-GGA无人机载温室气体分析仪适用于大面积区域或人类难以进入区域的温室气体排放的高空测量,具有灵敏度高、灵活性高、机动性强、监测面积大等优点。GLA133-GGA无人机机载温室气体探测可对温室气体垂直廓线的直接测量,结果具有更高的垂直分辨率与检测精度。

通过近地面机载观测不仅能够精准稳定获取空间信息,而且能够弥补野外站点观测在空间连续性、区域一致性以及观测精度上的不足,解决卫星遥感时空分辨率过低以及与地面监测校准尺度不匹配的问题,成为温室气体监测的一项重要辅助手段。煤炭作为我国的主体能源、重要的工业原料是保障能源安0稳定供应的基石。“双碳” 背景下,在巩固煤炭兜底保障作用的同时促进煤炭清洁高效利用,构建智能装备与现代煤炭开发的深度融合,对于我国煤炭产业可持续发展至关重要中煤电气有限公司作为中煤集团0资子公司是目前0国煤炭系统产品业务0广、涉及领域0多的综合电气自动化企业之一,在“双碳”长期目标指引下,以科技为依托,0注于推动煤炭行业与新能源耦合发展,为煤炭行业智能化、数字化转型持续贡献中煤力量。近日,ABB为中煤大屯电厂及大屯姚桥煤矿提供iVD4中压智能化解决方案,助力其实现从“人控”到“数控”运维的0面升级提速,加速迈进智能化时代。

中煤大屯电厂坐落于以煤炭为支柱产业的江苏省徐州市,前身为从事供电、发电50余年的徐州大屯发电厂,承担着大屯矿区工业生产、职工生活的供电、供热业务。该发电厂远距城市中心数十公里,运维人员流动率高且招工困难。早期,电厂采用人海战术“24小时三班倒”(每个开闭所配置多人,每8小时轮班),不仅导致非0业人员“臃肿”,还易发生运维漏检、错检等不足,在实际运行中存在巨大的安0隐患。ABB以中煤大屯电厂安0可靠的运营需求和绿色发展规划为核心,为其提供iVD4®中压开关智能化解决方案,在帮助电厂降低运维成本的同时帮助其提高0生命周期稳定、持续运行。项目中采用的VD4中压真空断路器和ConVac中压真空接触器的智能化解决方案具有丰富的数字化监测与诊断功能,可根据不同的配电回路情况实时监控设备运行状况,使配电室实现对分散配电系统参量的0面监控,帮助运维人员快速锁定故障点,提前发现设备隐患,保障供电稳定性和连续性。不止于智能化的解决方案,iVD4中压真空断路器更是绿色环保的利器。作为通过中国环境标志(Ⅱ型)认证和碳足迹双重认证产品,ABB VD4真空断路器采用创新的环保型绝缘材料(PT极柱),告别三废污染(废水、废气和固体废弃物),是绿色电气化的可持续推动者,有效帮助发电厂节能减排,实现绿色低碳发展目标。

Everyone who studies electronics knows that PLC is a very important device and a relatively difficult technology. It is a digital operation electronic system specially designed for application in the industrial environment. It is the basis for realizing industrial automation and Internet of things control. It has a very broad application prospect in the future.

1538104686246084971. png

PLC technology originated in the United States

PLC technology originated in the United States. General Motors of the United States was the first to apply PLC. In the 1960s, when they adjusted the factory production line, they found that the relay and contactor control system was difficult to modify, large in size, noisy, inconvenient to maintain and poor in reliability. Subsequently, the American digital equipment company developed the first programmable controller, which has achieved remarkable results in the production line of general motors. Later, PLC technology was developed in Japan and Europe, and programmable controllers were successfully developed in Japan and Germany. In 1974, China also began to study programmable controllers and widely used in various fields.

PLC first replaced the mechanical switch device, and then the function of PLC gradually replaced the relay control board. Modern PLC has more functions, and its purpose extends from single process control to the control and monitoring of the whole manufacturing system.

Application of PLC technology in industrial automation, Internet of things control and other fields

At present, PLC technology is widely used in industrial automation, automotive electronics, transportation, Internet of things control and other industries. Its role in these fields can be roughly divided into four categories.

1、 For various motion control

PLC controller is a kind of digital electronic equipment with microprocessor. It is a digital logic controller used for automatic control. It can load control instructions into memory for storage and execution at any time. The programmable controller is modular composed of internal CPU, instruction and data memory, input and output unit, power module, digital analog and other units. PLC controller can be used to control circular motion or linear motion. Nowadays, almost all the main PLC controller products have motion control function. It is used in various machinery, machine tools, robots, elevators and other occasions.

In terms of control mechanism configuration, in the early days, it was directly used for switching value i/o modules to connect position sensors and actuators. Now, special motion control modules are generally used, such as single axis or multi axis position control modules that can drive stepper motors or servo motors.

2、 Realize industrial process control

As an industrial control computer, PLC controller can compile various control algorithm programs to complete closed-loop control. In industrial process control, PLC is mainly used for closed-loop control of analog parameters such as temperature, pressure and flow. All large and medium-sized PLCs have PID modules. PID regulation is a regulation method commonly used in general closed-loop control systems. At present, many small PLC controllers also have this function module.

3、 Realize relevant data processing

Modern PLC controller has the functions of mathematical operation, data transmission and conversion, and can complete data collection, analysis and processing; These data can be compared with the reference values stored in the memory to complete certain control operations, and can also be transmitted to other intelligent devices using the communication function. In large-scale control systems, such as unmanned flexible manufacturing system, PLC controller is one of the core components.

4、 PLC communication and Internet of things

As the general trend of industrial Internet of things, the relevant technologies of PLC communication and Internet of things will be popular in the future. General PLC controller communication includes communication between PLC controllers and communication between PLC controller and other intelligent devices. With the development of industrial control automation, all PLC controller manufacturers attach great importance to the communication function of PLC controller, and have launched their own network systems. New PLC controllers have communication interfaces, which is very convenient for communication.

1538104705109085277. png

PLC technology has great potential in industrial control and Internet of things market

Three characteristics of future PLC Technology

1. Miniaturization and integration are getting higher and higher: with the requirements of the market for miniaturization and integration, PLC technology is more integrated into industrial, automotive, communication and other products. PLC products are characterized by control and data processing. While meeting the functions, the process requirements are more refined.

2. Intelligent PLC technology: with the development of AI technology, more products are endowed with intelligent functions, and PLC is no exception. For example, the intelligent i/o module of PLC used in industrial control and the intelligent temperature control module used in automobiles will have more application scenarios in the future.

3. Diversified PLC technologies: including PLC related programming languages and tools. With the deepening of application scenarios, one or several programming languages cannot achieve all functions, customized PLC products will increase, and PLC modular technologies will also increase.

Great potential of PLC market in China

Today, PLC technology is developing rapidly. According to statistics, there are more than 300 PLC manufacturers and more than 500 PLC products in the world. The United States, Europe and Japan are the main production places, with a market share of more than 60%. There are A-B companies, general electric and Modicon in the United States; Siemens and AEG in Germany; Te company in France; Mitsubishi, Omron and Panasonic in Japan are all famous PLC suppliers.

In recent years, with the attention of the state and enterprises, China's PLC industry has maintained rapid growth, and there have also been some influential enterprises in China, such as Delta, Huichuan, Hexin, Yiwei, Kewei and Lishi. According to relevant data, the scale of China's PLC market in 2017 was 10 billion yuan, and it is expected to maintain a growth rate of 20% in 2018. Domestic PLC products have very good cost performance and service, which has brought them a good reputation and market.